Oil Liquid Abrasive Particle Intelligent Detector

Project Overview

The Oil Wear Particle Detector (EIDCS-1A) is designed for high-precision, high-volume fluid sampling, and frequent testing scenarios. The product was demonstrated and validated on-site at the Daishan and Benniu Airbases of the East Sea Fleet, where it was used to analyze lubricating oil from various aircraft engines. The successful trials confirmed its key features, including high intelligence, accurate built-in standard calculations, user-friendly operation, and efficient data storage capabilities. Detailed results can be found in the trial report.

Konghang International has decades of technical expertise within the aviation industry, particularly in aircraft engine research and development. Our team includes leading experts and extensive technical resources focused on engine systems, with in-depth knowledge of various engine models and their maintenance requirements. We have developed numerous specialized testing equipment for engines, including over 100 units of the "EIDCS-1A" Oil Wear Particle Detector, which has been delivered to both the Air Force and Navy. This device, also known as the Oil Wear Particle Analyzer, Large Particle Analyzer, or Automatic Wear Particle Detector, is highly effective for detecting engine faults, oil contamination levels, wear particles, and debris in various military aircraft engines. Currently, hundreds of units are in service with the Air Force, and dozens with the Navy. Our proprietary intelligent control software and functional modules provide unique capabilities for real-time engine oil monitoring.

Given its critical role in engine condition monitoring, the device has been officially recognized through the issuance of a Technical Bulletin, highlighting its irreplaceable importance in maintaining operational safety and efficiency.

Performance Characteristics

1. The main performance parameters of the Oil Liquid Abrasive Particle Intelligent Detector are as follows:

a. Single oil sample injection volume: <10 ml; Detection time: ≤3 minutes;

b. Real-time capture of abrasive particle images: The acquisition frequency can be automatically adjusted and set according to the flow rate, with an acquisition frequency of 33f/ps. The collected abrasive particle images can be automatically stored;

c. Abrasive particle identification: All particles with a major axis size greater than 10 microns are automatically identified as cutting abrasive particles, sliding abrasive particles, fatigue abrasive particles, and non-metallic particles;

d. Particle contamination level detection: Count particles with an equivalent circular diameter greater than 4 microns, calculate the size and concentration distribution, and provide contamination level grades in accordance with the standards of GJB-420A-96, GJB-420A-87, NAS1638, and ГОСТ17216;

e. Expert system: The equipment integrates independently developed expert system software. The generated data package can be judged using the same expert system software as the lubricating oil spectrum analysis monitoring, facilitating data storage and analysis. It also has functions such as image acquisition and analysis, fault diagnosis, trend analysis, and data management.

2. Service life: The service life is not less than 10 years, the storage period is 3 years, and maintenance is performed as needed;

3. Interface requirements: 4 USB interfaces, 1 VGA interface, 1 LAN interface;

4. Overall dimensions: 400mm × 270mm × 260mm;

5. Weight: 16kg;

6. Power supply requirements: It can work normally under the AC power supply of (110~250) V/50 Hz;

7. Automatic sampling, automatic cleaning, and automatic identification of non-metallic particles and fibers.

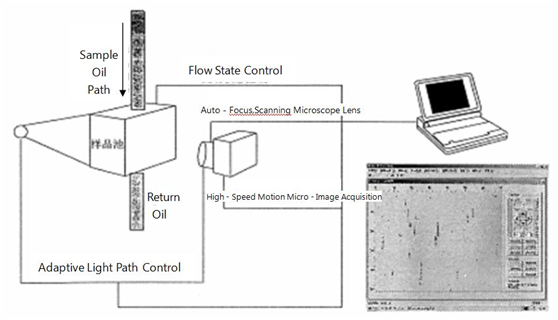

Working Principle

In the fluid channel, oil is driven by an automatically controlled peristaltic pump through an optically precise sample cell, which is installed in a transmission-reflection optical path lighting system. A long-focus microscopic optical lens, controlled by a computer for automatic focusing and tomography, performs real-time dynamic imaging of particles in the oil flowing through the sample cell. After the particles in the fluid are magnified and imaged, the image signals are captured by a high-speed CCD, then transmitted to the computer for processing via an image acquisition card (A/D). The computer system analyzes the collected particle images through software to identify the morphological characteristics of the particles, determine the type and quantity of abrasive particles, and assess the oil contamination level. This enables monitoring of the wear status of the engine system, fault trend analysis, and expert diagnosis.

Technical Indicators

1. Measurement range: Oil viscosity: 15–320 CST;Particle size: 4 μm–100 μm

2. Oil sample injection volume: 0.3–0.5 ml

3. Industrial computer parameters: 12-inch touch screen,CPU frequency: 2.3 GHz,Memory: 4 GB,Hard disk: 250 GB

4. Equipped with automatic imaging and abrasive particle identification technology, enabling abrasive particle trend analysis

5. Capable of outputting images of particles larger than 10 μm

6. Intelligent classification of particles larger than 10 μm into types such as cutting wear particles, contact/sliding wear particles, fatigue wear particles, non-metallic abrasive particles, fibers, bubbles, and water droplets

7. Automatic sampling, automatic cleaning, and automatic identification of non-metallic particles and fibers

8. Equipped with a visual cleaning function, allowing real-time observation of the sample cell cleaning process

9. Built-in contamination level evaluation standards such as GJB420A-96, ISO4406, and NAS1638; supports user-defined contamination level evaluation standards

10. Testing time: ≤ 3 minutes

11. Contamination level error (compared with MTD standard oil): no more than ±1 level

Contact Information

Tel: 18515136109 / 18500199966

Landline: 400 006 2299 ext. 1

Address:Jiayue Plaza, Daxing District, Beijing